Light Sources for Architectural Lighting

Edition 1.1 – (2000)

Copyright (c) 1999-2000 by Bill Williams

1.0) INTRODUCTION

The modern lighting specifier has many different choices regarding the selection of light sources for architectural lighting applications. This was not always the case. One hundred years ago, practical electric lighting was largely limited to the incandescent (electric filament) lamp. Early incandescent lighting was quite inefficient by today’s standards, however it offered a much better alternative to both oil and gas lighting of previous days. During the 20th Century, there was a explosion in the development of new light sources, starting with the introduction of the fluorescent lamp in the 1930’s. The latter half of the Century resulted in many new light sources being either developed or further refined.

Today, the lighting designer can chose from; incandescent, tungsten halogen, fluorescent, mercury, metal halide, high pressure sodium, low pressure sodium, cold cathode, neon, light emitting diode, induction lamps, sulfur lamps, and other new light sources.

Light sources for the human environment are evaluated and selected in respect to their light or lumen output, their lumen efficacy, color temperature, color rendering index and life. Other considerations include initial cost, operating cost and maintenance cost. A brief description of the more important properties, follows:

2.0) LUMINOUS EFFICACY

Lamp ‘efficacy’ refers to the ‘lumens per watt’ produced by different types of light sources. The ‘lumen’ is the name of the unit used in measuring the amount of light given off by a light source. The higher the lumen efficacy, the more efficient the source is at producing light.

Edison’s first electric filament lamp produced only 1.4 lumens per watt. Research over the years slowly brought improvements in lamp efficiency. The common incandescent lamp of today, produces approximately 15-25 lumens per watt. The balance of the electrical energy is transformed into heat. It is estimated that 40 lumens per watt is about as high as can be obtained by a tungsten filament, just before it reaches the melting point (3370 degrees C.)

About 1938 the lighting industry was revolutionized with the introduction of the fluorescent lamp. Lumen efficacies were suddenly raised and today the modern fluorescent lamp has an efficacy of between 65 and 100 lumens per watt.

Luminous efficacy increased again with the development of the Metal Halide and High Pressure Sodium lamps, to up to 140 lumens per watt. The Low Pressure Sodium lamp pushed efficacy up to about 200 lumens per watt.

Scientists have determined that if all of the electrical energy put into a lamp could be converted into white light, a lamp would give out 220 lumens for each watt of energy put in.

Today the lighting designer should endeavor to use the most efficient light source possible while still maintaining proper color rendering qualities required by the specific lighting application.

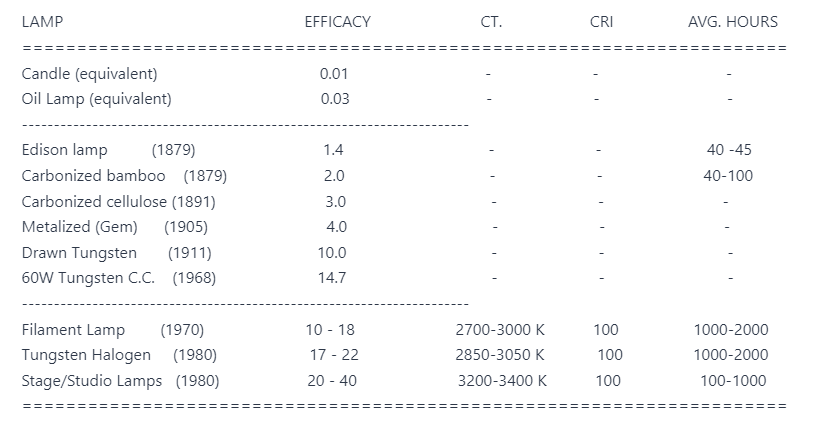

The following table shows how lumen efficacies have gradually increased over the years.

3.0) COLOR TEMPERATURE

As most objects are heated they give off light. As the temperature is raised the object first glows red, then yellow, white, pale blue and then finally brilliant blue. Color temperature is a measure of the ‘whiteness’ of a source and is expressed in degrees K. (Kelvin).

Tungsten filament lamps used for general lighting applications have color temperatures of between 2600 and 3000 degrees Kelvin. Stage and studio lamps used for theatre and television applications generally have a color temperature of between 3000 and 3400 degrees Kelvin.

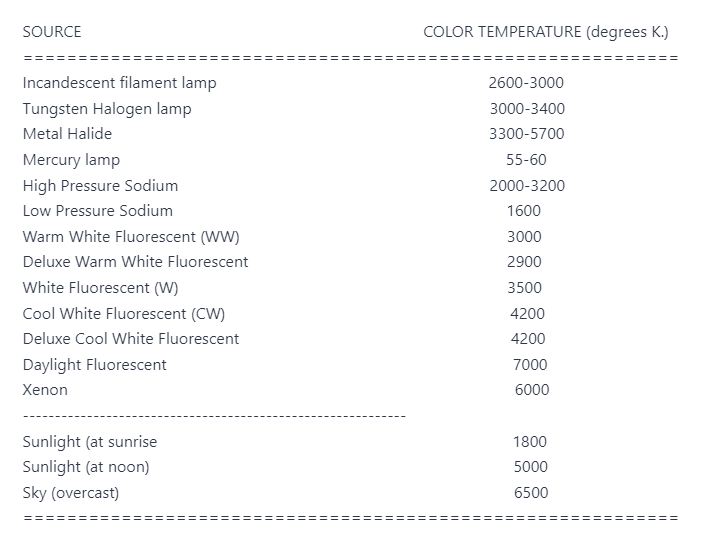

The specification of color temperature technically applies only to incandescent lamps. The term ‘apparent color temperature’ (or correlated color temperature) is often used however to describe the degree of ‘whiteness’ for fluorescent and H.I.D. (high intensity discharge) lamps. Color temperatures (and apparent color temperatures) of common sources are as follows:

4.0) COLOR RENDERING INDEX

Although ‘color temperature’ is a measure of the visual ‘whiteness’ of a source, it does little to specify the source’s ability to accurately show colors. This is referred to as the color rendering index (or CRI) of a light source.

The modern electric filament lamp produces a continuous spectrum with all colors present. As a result this lamp has a high CRI of 100 as it renders all colors ‘correctly’ to the eye.

5.0) LAMP LIFE

Generally, a source type with the longest possible life should be selected for any particular lighting application. A long life lamp however should not be used at the expense of providing proper lumen efficacy, color temperature and CRI requirements.

6.0) SUMMARY AND CONCLUSIONS

The modern lighting specifier must be knowledgeable and aware of light source characteristics, particularly as applied to lighting for the human environment. It is important not to select a light source based on efficiency alone. Although lamp efficacy is very important, the color temperature and color rendering index must also be carefully considered. Other factors that must be considered include the initial cost of light source (and lighting system) in relationship to operating costs (and life). A light source with a low initial cost, may have a very high operating cost. Conversely a light source with a higher initial cost, may have a lower associated operating cost.

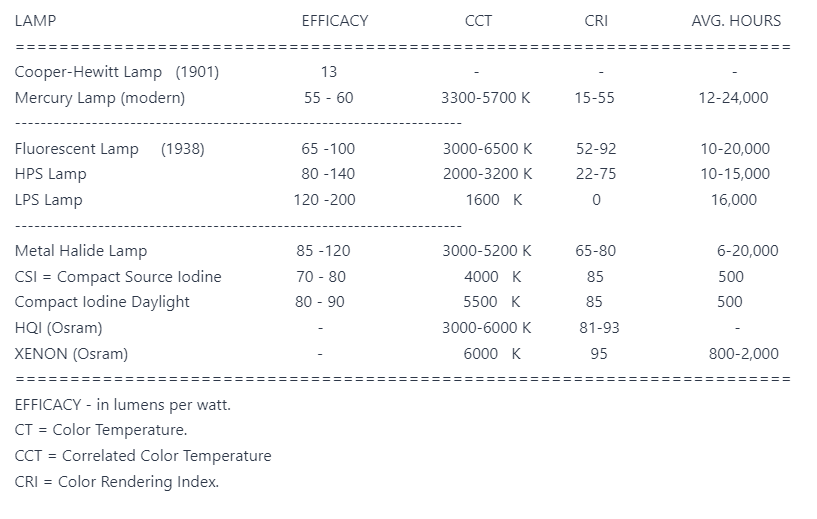

The following tables provide a summary of efficacy, color temperature, color rendering index, and life – for common incandescent and discharge light sources.

Table 1 – Incandescent Sources

Table 2 – Discharge Sources

Bill Williams is a Canadian lighting designer and consultant, with over 30 years of experience in entertainment and architectural lighting. With over 500 project credits he has worked throughout Canada, and in the USA, Britain, Europe, South America and Asia.